When tackling a new machine embroidery project it is always important to have the right equipment and material on hand. We have already discussed the importance of choosing the right needle, but now we are going to delve further into the use of stabilisers.

For those of you who have done a little bit of research online, you will have seen a lot of advice leaning towards using test samples to zone in on the right stabiliser for your project. The overwhelming number of stabilisers on the market however, may make this an impractical starting point for those unwilling to kick their families out to make room for machine embroidery supplies. This isn’t to say you shouldn’t use test samples of material and stabiliser once you have a better idea of which kind to use. Using test samples is also a great way to find out if stabilisers work well together as sometimes using a single heavy duty product is less effective than using two lighter products.

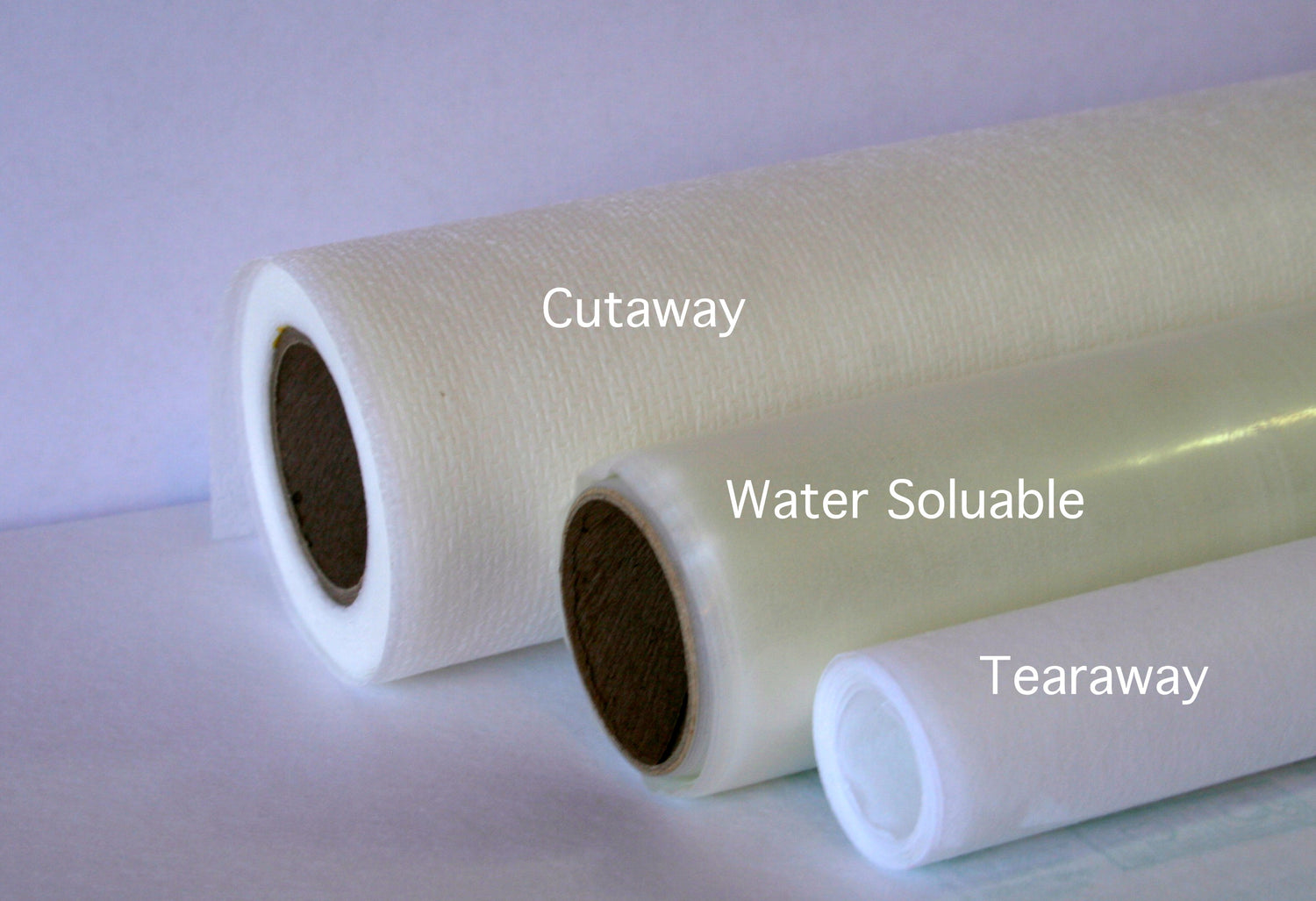

Different Kinds of Stabiliser

There are essentially four kinds of stabiliser that that can be used for in-the-hoop and hooped machine embroidery designs. These are cut-away, tear-away, heat-away and wash-away. These are all best suited to certain kinds of designs or materials, and will usually have usage advice on the packet.

Cut-Away

Cut-away stabilisers are only partially removed once a machine embroidery design is complete. The excess stabiliser is as the name suggests, cut away, leaving a section over the design to aid in holding it together. This is a great stabiliser when the material being used is particularly loosely stitched or hand-knitted. It may also be a good idea to use this type of stabiliser for designs that may be subject to daily wear and tear like clothes or bibs. The big drawback for cut-away on some designs however is that the stabiliser may be visible and therefore not ideal for every situation. Another variety of cut-away stabiliser available is a soft mesh stabiliser. They are great where the stabiliser will remain but you want a soft finish. An example of this would be a quilt in the hoop design. Click here to buy Cut-away stabiliser.Tear-Away

For machine embroidery designs where it is undesirable or impractical to have any residual stabiliser on the finished item, a tear-away will be preferable over cut-away. Once a design is finished, these are carefully torn from around the stitches. It is very important to test this style of stabiliser before use, as certain brands and heavier duty products don’t tear as easily as others or tear while in the hoop. The last thing you want to do is create a beautiful design only to have stitches come loose when removing the stabiliser. It may also be a good rule of thumb to use multiple lighter gauge sheets than one heavier gauge as they will be easier to tear and can be removed individually. We use tear- away stabiliser in most of our zipper purse in the hoop designs as the stabiliser needs to be removed from the zipper opening. Click here to buy Tear-away stabiliser.Heat-Away

Essentially heat-away stabilisers should be used when the other three kinds wouldn’t be effective (If the material isn’t washable and too delicate for tear-away or cut-away). It goes without saying that this method isn’t usable for materials that will be damaged by heat, although most won’t be damaged by an iron. There are two kinds of heat-away stabilisers, one that will be removed completely and one that will offer extra support to the project while losing any excess visible stabiliser. Both kinds are removed with an iron, and it is important not to use steam in the removal, as the stabilisers can be water soluble once melted and may embed in the material. We have another blog which explains this process in more detail here, as well as a YouTube video.

Wash-Away (soluble)

Finally we have wash-away stabilisers, which can be used effectively for a wide range of machine embroidery designs and are perfect for delicate and mesh fabrics. There are a number of wash-away stabilisers that come in the form of a spray that can be applied to a material and hardens like a resin. These can be great for uneven materials that would leave gaps with a sheet style stabiliser. They can also be some of the most versatile stabilisers on the market. The big drawback for wash-away with certain projects is of course their method of removal makes them completely impractical for any design that will need continued support post-wash. We use this type of stabiliser for all our ornament type in the hoop designs. It is preferable to use over tear-away in this situation as tear-away can leave a fine edge of stabiliser remaining which may be seen on the completed project. Click here to buy Wash-away stabiliser

Try it Out

I hope this has shed some light on the different kinds of stabilisers available. Remember to always read the usage advice on the packet and try test samples before beginning any machine embroidery design project. Click here to buy Sweet Pea recommended stabiliser

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.